PRODUCT

Changzhou Danmude Tools Manufacturing Co., Ltd.

Add:No.58, Weishanhu Road, Xixia Villas, Xinbei District, Changzhou City

Tel:86-0519-83433877

Fax:86-0519-83440699

Mobile:186 0525 3588

E-mail:dmd@czzl.cn

Cutting Tool Modification

Seven professional cutting tool grinding advantages ensures the quality.

Cutting tools are a founder of grinding philosophy and grinding standards in China. We have set up cutting tool grinding centers in 12 important industrial cities of China, which focus on the grinding of cemented carbide cutting tools, superhard cutting tools and other cutting tools with high grinding requirements as well as the need of professional equipment and professional technologies.

Perfect grinding hardware

SkTechnicians with abundant cutting tool grinding experience, dedicated and professional service

Accurate grinding accessories

Accurate grinding CBN grinding wheels, diamond grinding wheels and corundum grinding wheels ensure accurate cutting tool grinding

Complete grinding standards

Give preference to different cutting tool parameters for different workpiece materials; establish different grinding methods for different cutting tools; establish professional grinding standards for customers with special requirements; track grinding effects, continuously improve grinding standards, and learn widely from other’s strong points.

Advanced inspection equipment

The world advanced inspection equipment accurately inspects rear angle and other key parameters, ensuring the properties of cutting tools.

illful grinding technicians

SkTechnicians with abundant cutting tool grinding experience, dedicated and professional service

Imported coating equipment

The imported high-technical-content equipment ensures excellent performance of coatings.

Strict quality management

High-standard quality management, attentive grinding for every cutting tool

List commonly ground cutting tools; Learn more common senses of cutting tool grinding

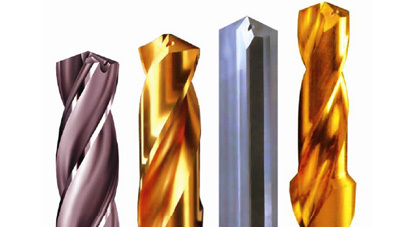

Drills

Drills are the most appropriate cutting tool for grinding, which have met the requirement of grinding in the designing process. The drill can be ground for 20 times for pre-machining or general hole precision, and can generally be ground for 5 times under the condition of higher precision.

Ball-end Milling Cutter

The ball-end milling cutter can be ground without diameter variation; however, the diameters of flat-end milling cutters will be reduced in the process of grinding side edges, which depends on specific machining conditions of users.

Reamer

The reamer is also a commonly ground cutting tool with a relatively simple grinding process, which can generally be ground for 2-5 times due to high precision. Do inspect whether the diameter of the reamer is in the required range or not before grinding. The reamer is generally not coated after being ground.

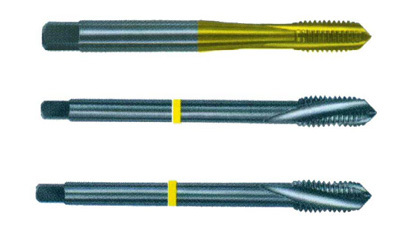

Screw Tap

The screw tap can be ground for 2-3 times, particularly a large-diameter screw tap, which mainly depends on the cost. Screw taps are generally not coated after grinding.

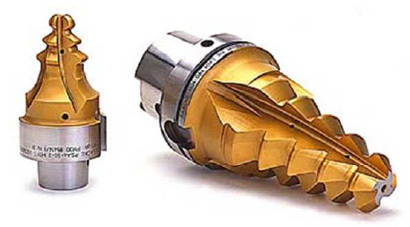

Complicated Profile Cutter

Complicated profile cutters must be ground because cutting tools are high in cost while the grinding cost is relatively low in cost.

FOLLOW US

The only designated website of DMD

Powered by:www.300.cn changhzou | label | Business license